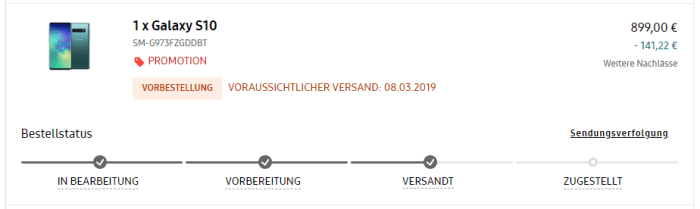

Samsung Galaxy S10 ship later than expected? Yeah, that totally bummed out a lot of people. The highly anticipated launch faced unexpected delays, leaving fans frustrated and analysts scratching their heads. From manufacturing hiccups to global supply chain chaos, the reasons behind the postponement are complex and offer a fascinating glimpse into the intricate world of tech launches. Let’s dive into what went wrong and what Samsung could do differently next time.

The delay wasn’t just a minor inconvenience; it had significant repercussions. Customers felt let down, potentially impacting Samsung’s brand reputation and bottom line. The ripple effect extended globally, affecting sales projections and potentially shifting market share. This case study provides a valuable lesson in the importance of robust supply chain management and transparent communication in the high-stakes world of consumer electronics.

Reasons for Delayed Shipments

The Samsung Galaxy S10 launch, while highly anticipated, faced unforeseen delays in shipments. Several interconnected factors, ranging from manufacturing complexities to global disruptions, contributed to this setback, impacting the availability of the device for eager consumers worldwide. Let’s delve into the key reasons behind these delays.

Manufacturing Bottlenecks

The intricate manufacturing process of a flagship smartphone like the Galaxy S10 involves numerous stages, each with its own potential for bottlenecks. A shortage of crucial components, such as specific processors or memory chips, can significantly hinder production. For instance, a delay in the delivery of a critical component from a supplier could halt the entire assembly line, resulting in a ripple effect across the production schedule. Similarly, unforeseen issues with the manufacturing equipment itself, requiring repairs or replacements, can lead to production slowdowns. These manufacturing hurdles often translate directly into delayed shipments, impacting the overall launch timeline.

Global Supply Chain Disruptions

The Galaxy S10’s production relies on a complex global supply chain, encompassing various countries and manufacturers. Any disruption within this network, no matter how seemingly minor, can have far-reaching consequences. Geopolitical instability in regions crucial to component sourcing can significantly impact delivery times. Trade wars or sanctions, for example, can create delays or even halt the flow of materials needed for production. Furthermore, logistical challenges like port congestion, transportation issues, or even extreme weather events can disrupt the timely delivery of components and finished products, delaying shipments to retailers and ultimately consumers. The interconnected nature of the global economy makes it particularly vulnerable to such disruptions.

Unforeseen Circumstances

Beyond predictable manufacturing and supply chain challenges, unforeseen circumstances can dramatically impact shipment timelines. Natural disasters, such as earthquakes or floods, can damage manufacturing facilities or disrupt transportation networks, causing significant delays. For example, a major earthquake affecting a key component supplier could lead to weeks or even months of production delays. Similarly, unexpected geopolitical events, such as political unrest or sudden changes in trade policies, can create unpredictable disruptions in the global supply chain, significantly affecting the timely delivery of the Galaxy S10. These unforeseen circumstances highlight the inherent risks associated with global manufacturing and distribution.

Internal Logistical Issues

Even with a smooth manufacturing process and a stable global supply chain, internal logistical issues within Samsung’s distribution network can contribute to shipment delays. Inefficient warehouse management, inadequate inventory tracking, or problems with order fulfillment can lead to delays in getting the devices to retailers and consumers. For example, a failure in Samsung’s internal tracking system could lead to misallocation of inventory, delaying shipments to certain regions. Similarly, issues with packaging or labeling could also create delays in the shipping process. These internal logistical challenges underscore the importance of efficient and reliable internal operations in ensuring timely product delivery.

Comparative Analysis of Samsung’s Response: Samsung Galaxy S10 Ship Later Than Expected

Samsung’s delayed S10 shipments weren’t their first rodeo. The tech giant has faced production hiccups and launch delays before, offering a valuable case study in crisis communication. Examining their response to the S10 delay against previous incidents, and comparing their approach to competitors, reveals both strengths and areas for improvement in their handling of such situations. This analysis aims to highlight best practices and potential areas of refinement for future product launches.

Samsung’s communication surrounding the S10 delay, while ultimately providing information, lacked the proactive and transparent approach some consumers desired. Past incidents, such as the Note 7 recall, demonstrated a more reactive communication strategy, initially downplaying the severity of the issue before issuing a full recall. This contrast highlights the evolution – or perhaps lack thereof – in Samsung’s crisis management approach. While the S10 delay didn’t involve safety concerns, the initial lack of clear communication created uncertainty and frustration among pre-ordered customers.

Samsung’s Response to Past Product Launch Issues

Analyzing Samsung’s past responses to product launch issues reveals a pattern of initially cautious communication, often followed by more detailed explanations as the situation unfolds. The Note 7 recall, for example, initially involved limited statements before escalating to a full-scale product recall and apology. This reactive approach, while ultimately necessary in the case of the Note 7, contrasts with the more proactive strategies employed by some competitors. A comparison with Apple’s handling of product launch issues reveals a difference in communication style; Apple tends to be more upfront, even if the initial information is limited.

Best Practices from Other Companies, Samsung galaxy s10 ship later than expected

Companies like Apple, often praised for their meticulous product launches, prioritize clear and timely communication, even when facing unforeseen delays. They frequently utilize multiple communication channels, including social media, press releases, and direct customer emails, to ensure all stakeholders are informed. Furthermore, they often offer proactive solutions, such as compensation or priority shipping for affected customers, to mitigate the negative impact of the delay. This proactive approach fosters customer loyalty and reduces potential damage to brand reputation.

Comparative Communication Strategies

| Company | Product Launch Issue | Initial Communication Strategy | Subsequent Communication Strategy |

|---|---|---|---|

| Samsung | Galaxy S10 Delayed Shipments | Delayed updates to pre-order customers, initial lack of specific reasons. | Subsequent announcements with explanations of the delay and revised shipping timelines. |

| Apple | iPhone X Production Delays (Example) | Early acknowledgement of production challenges and revised launch date. Proactive communication through various channels. | Consistent updates on production progress and shipping estimates, emphasizing the improved product features. |

The Samsung Galaxy S10 delay serves as a stark reminder that even the biggest tech giants aren’t immune to unforeseen circumstances. While the initial disappointment was palpable, the incident offers valuable insights into risk management and crisis communication. By analyzing the root causes of the delay and comparing Samsung’s response to industry best practices, we can learn how to navigate similar challenges more effectively in the future. Ultimately, the S10 saga underscores the need for proactive planning and transparent communication to maintain customer trust and minimize the impact of unexpected setbacks.

Tech Nest Online Berita Teknologi Terbaru

Tech Nest Online Berita Teknologi Terbaru