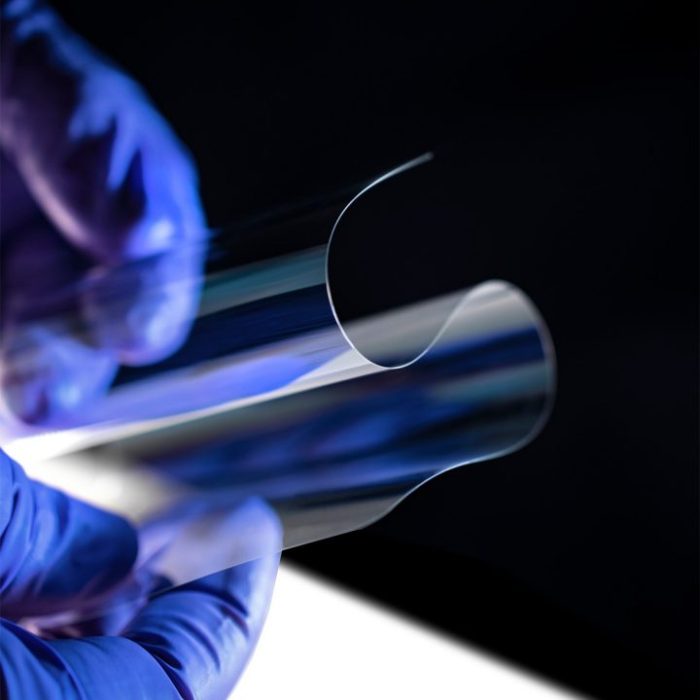

Corning developing flexible glass foldable displays? It’s not science fiction anymore. Forget clunky, breakable screens; imagine phones that fold like paper, tablets that morph into laptops, and wearables that seamlessly integrate into your life. This is the future Corning is building, one incredibly thin, durable sheet of Willow Glass at a time. We’re diving deep into the technology, the challenges, and the mind-blowing potential of this revolutionary material.

From the groundbreaking properties of Willow Glass—its flexibility, durability, and surprisingly simple manufacturing process—to the myriad applications spanning consumer electronics, wearables, and beyond, we’ll explore the impact of flexible glass displays on our tech-driven world. We’ll also tackle the hurdles Corning faces in mass production, the competitive landscape, and the environmental considerations of this innovative technology. Get ready to bend your expectations.

Market Competition and Analysis

The flexible display market is a fiercely competitive arena, with Corning’s Willow Glass vying for dominance against a range of established players and innovative newcomers. Understanding the competitive landscape and Corning’s strategic positioning is crucial to assessing its future prospects. This analysis will compare Corning’s technology to its competitors, identify key players, and detail the overall market dynamics.

Key Players in the Flexible Display Market

The flexible display market is dominated by a handful of major players, each with its own strengths and weaknesses. These companies represent a diverse range of technological approaches, from Corning’s glass-based solutions to plastic-based alternatives. Samsung Display, LG Display, and BOE Technology are consistently ranked among the top producers of flexible AMOLED displays, leveraging their substantial manufacturing capacity and established supply chains. Meanwhile, smaller, more specialized companies are focusing on niche applications and emerging technologies. This dynamic interplay of established giants and innovative startups shapes the market’s competitive intensity.

Comparison of Corning’s Flexible Glass with Alternative Technologies

Corning’s Willow Glass boasts several advantages over competing technologies, primarily its superior durability and scratch resistance compared to plastic-based alternatives. However, it faces challenges in terms of cost and manufacturing scalability compared to the high-volume production capabilities of AMOLED manufacturers.

| Technology | Material | Advantages | Disadvantages |

|---|---|---|---|

| Corning Willow Glass | Glass | High durability, scratch resistance, optical clarity | Higher cost, potentially lower flexibility compared to plastic, challenges in mass production |

| AMOLED (Samsung, LG, BOE) | Plastic substrate with OLED | High color accuracy, flexibility, lower cost per unit (at high volumes), established manufacturing infrastructure | Susceptible to scratches, burn-in potential, lower durability compared to glass |

| Flexible LCD (various manufacturers) | Plastic substrate with LCD | Relatively low cost (depending on size and resolution), established technology | Lower color accuracy, lower contrast ratio, less flexible than AMOLED |

| Other emerging technologies (e.g., MicroLED) | Various | Potential for higher brightness, efficiency, and durability | High manufacturing cost, limited availability, technology still under development |

Corning’s Market Position and Competitive Landscape, Corning developing flexible glass foldable displays

Corning’s market position is characterized by a focus on supplying its glass substrate technology to other display manufacturers rather than directly competing with them in the finished product market. This strategy allows Corning to leverage its material expertise while avoiding the intense competition in the consumer electronics sector. However, this also limits its direct market share and revenue potential compared to companies like Samsung and LG, who control the entire value chain. The competitive landscape is highly dynamic, with ongoing technological advancements and shifting market demands constantly reshaping the competitive dynamics. Corning’s success hinges on its ability to maintain its technological edge, improve cost-effectiveness, and secure strategic partnerships with major display manufacturers. The future will likely see increased collaboration and consolidation within the industry, as companies seek to optimize their supply chains and reduce costs in the face of intense competition.

Environmental Impact and Sustainability: Corning Developing Flexible Glass Foldable Displays

The rise of foldable devices presents a fascinating paradox: sleek, innovative technology juxtaposed with the environmental consequences of its production. While flexible glass displays offer a compelling user experience, understanding their environmental footprint and the sustainability efforts of manufacturers like Corning is crucial for responsible technological advancement. This section delves into the environmental impact of flexible glass display manufacturing, Corning’s sustainability initiatives, and a comparison with traditional display technologies.

The manufacturing process of flexible glass displays, like any technologically advanced product, involves energy consumption, material extraction, and waste generation. Energy-intensive processes such as high-temperature treatments and chemical processing contribute to greenhouse gas emissions. The sourcing of raw materials, including silica sand (a primary component of glass), also has an environmental impact, potentially involving land use changes and water consumption. Furthermore, the manufacturing process can generate various types of waste, including chemical byproducts and broken glass fragments, requiring careful management and disposal.

Corning’s Sustainability Initiatives in Flexible Glass Production

Corning has implemented several initiatives to mitigate the environmental impact of its flexible glass production. These efforts focus on reducing energy consumption, improving water efficiency, and minimizing waste generation. Specific examples include the adoption of more energy-efficient furnaces, optimized production processes to reduce material waste, and the implementation of closed-loop water systems to recycle and reuse water in the manufacturing process. Corning also actively works to source raw materials responsibly, prioritizing suppliers with strong environmental sustainability practices. These initiatives demonstrate a commitment to minimizing the environmental footprint of their operations.

Comparison of Environmental Footprints: Flexible Glass vs. Traditional Displays

A comprehensive life-cycle assessment (LCA) comparing the environmental impact of flexible glass displays to that of traditional LCD or OLED displays is necessary for a precise comparison. However, preliminary analyses suggest that while flexible glass manufacturing might have a higher initial energy consumption due to the specialized processes involved, its potential for longer product lifespans and improved durability could offset some of these initial impacts. Traditional displays, particularly those using less sustainable materials or with shorter lifespans, may have a higher overall environmental impact when considering their entire life cycle. The reduced weight of flexible glass displays also contributes to lower transportation emissions compared to heavier traditional displays.

Recycling Potential of Corning’s Flexible Glass

Corning is actively researching and developing recycling processes for its flexible glass. The goal is to create a closed-loop system where used flexible glass can be reclaimed and reused in the manufacturing process, minimizing waste and conserving resources. While specific details on the recycling technology are proprietary, the company’s commitment to circular economy principles suggests that future developments will likely focus on efficient and environmentally sound recycling methods. This would significantly reduce the environmental burden associated with the end-of-life management of flexible glass displays.

The quest for bendable brilliance is on, and Corning’s flexible glass is leading the charge. While challenges remain in scaling production and cost-effectiveness, the potential of flexible displays is undeniable. Imagine a future where screens are seamlessly integrated into our clothing, our homes, and even our bodies. Corning’s Willow Glass technology is paving the way for a world where screens are no longer rigid limitations, but adaptable interfaces shaping the future of technology. The possibilities are, quite literally, endless.

Tech Nest Online Berita Teknologi Terbaru

Tech Nest Online Berita Teknologi Terbaru